How to Build Your Own Sprayer Drone Leave a comment

Sprayer and plant-protection drones are new tools available to farmers and can be used to apply pesticides to small land areas and acreages. This type of sprayer can access land that is either too wet or otherwise inaccessible by humans and can provide greater spray infiltration into the plant canopy. Also, people are removed from spraying operations, which can greatly help reduce chemical contamination to humans. The disadvantages are that most sprayer drones can only carry 1 to 2 gallons of liquid and only fly for 10 to 20 minutes. For commercial use they may require fairly rigorous certifications, including Federal Aviation Administration Regulations Part 137 and Part 107 and other state and local certifications. Still, plant-protection drones may be useful in Louisiana, where the wet climate and different types of crops, including rice, horticulture and others, create a large need for small-area spraying. They may also be beneficial in areas inaccessible to trucks or spray planes. Typical uses in Louisiana are spraying levees, fence rows, briar patches, horticultural and vegetable plots, and tight field areas with obstructions. Note that these sprayers create a large air blast to hold the drone up, so spraying heights are typically higher (10 to 12 feet) than regular ground sprayers, and some damage can occur to fragile crops if the spraying height is too low.

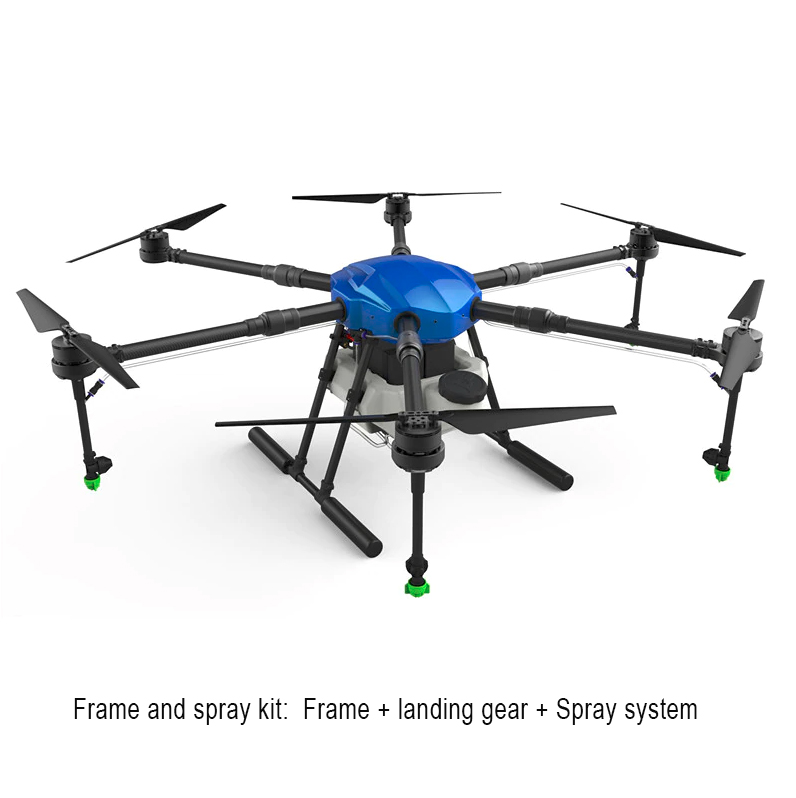

Buying a plant-protection drone can be quite expensive, costing $15,000 or more. We have found that it is possible to build your own sprayer and plant-protection drone in the $2,000-to-$3,000 range. Free software is available (www.DIYdrones.com) that has advanced to the point that height and position can be held to exact levels with a good range finder. Sprayer kits are also available from manufacturers. An example of a sprayer drone we built for under $2,500 is shown in Figure 1.

This drone carries three-quarters of a gallon of liquid, has a 10-minute flight time, is easy to fly and was constructed from the following components:

- Four (4) plant-protection motors (Gartt ML6011 340 kV Brushless Motors, $70 each)

- Four (4) helicopter, soft start, electronic speed controllers (YPG 100 Amp Brushless ESC, 2 to 6S LiPO, $53 each)

- Two (2) 18,000 mAh batteries ($350 each)

- One 6-to-12 channel radio ($150 to $550)

- Pixhawk flight controller kit (flight controller, GPS, power module, radio link, $150 to $300)

- Laser range finder (Lightware SF-O2, $300)

- Aluminum X-frame (1-inch by 1-inch aluminum, 3.5-inch long arms with ¼-inch aluminum motor mounts, $100)

- Sprayer kit for drone (5 liter) (landing gear frame, boom, pump and nozzles by http://www.innofpv.com, $250)

- Software for the drone is free from diydrones.com and includes built-in sprayer functions. However, you may not always need these as many sprayer pumps are pressure regulated and only need an on/off switch.

Things to note:

If you don’t feel like building a sprayer drone, some older models can be found on the internet in the $5,000-to-$8,000 range. If you do build your own, note the following:

- A range finder is necessary to adequately hold the low-altitude flights needed for crop spraying. We used a laser-type range finder.

- The ardupilot software (versions 3.5.5 and up) contains automatic terrain-following functions that will work with the laser range finder, and sprayer functions are available (versions 3.4.4 and up).

- The “loiter” function works well for spraying operations by holding altitude and controlling forward-travel speed.

Note the following when selecting ESCs (electronic speed controller):

- Make sure the ESCs are helicopter rated because airplane-type speed controllers may not work well without substantial programming. We tried three different types of ESCs and finally used slow-start helicopter ESCs from YPG that worked well out of the box with no programming needed.

- When choosing motors, two kV (RPM per volt) ranges are available: The higher kV ranges are for lower voltage systems (24 to 28 volts), and lower kV ranges are for higher voltage systems (35 to 48 volts). Most homemade drones currently use 24-to-28-volt systems, but higher voltage systems, which will reduce amperage flow, are possible.

- Be careful with bolt lengths when mounting the motors, as the windings can easily become damaged if the bolts protrude too far into the housing.

- Professional drone frames can be purchased but will greatly add to cost of the drone ($500 to $1,200 extra). Our frame was constructed from standard 1-inch-by-1-inch (or similar) aluminum tubing and motor mounts were made from a one-quarter-inch aluminum plate.

- Most drones in this category have a 3-to-5-foot frame width (although other sizes are possible).

- Use two or more batteries in parallel because one battery cannot typically handle the current usage of these types of drones.

- Do not use the power module to transmit full battery power because large-current flows can de-solder connector tabs. Use a separate battery lead for each battery. The power module can be wired separately to either carry the amperage flow from one battery or to the flight controller alone. In this case, the module will still report battery voltage to the ground station, which can be used to determine battery levels.

- When soldering wires, make sure they have enough contact to support the high amperage flow that can occur in these drones (80 to 200 amps). Use high-quality solder (60/40) and a large high-watt soldering iron (greater than 60 watts). Solder motor and ESC wires with at least one-quarter inch of parallel contact area — not end to end. When soldering multiple wires together, a clamp maybe required to hold wires together during soldering or an ESC power board should be used.

During operation, keep the following in mind:

- Carbon fiber props can cut bare skin like saw blades. BE CAREFUL WHEN WORKING AROUND THESE PROPS!

- Always remove the props when calibrating ESCs.

- Note that any drone used in the U.S. (under Part 107 or recreational use) may not weight more than 55 pounds at takeoff.

- Always test a newly built drone for correct operation without the propellers. During initial testing you can attach a large weight to the bottom of the drone or fly under a large and enclosed tree canopy for safety.

Spray System

The original green flat-fan nozzle tips that came with the spray system produced an extreme amount of driftable fines in the spray pattern. We used yellow A.I. (air induction) flat-fan tips at low pressure (0.1 GPM) to produce the droplet size pattern shown in Figure 2. These nozzles greatly reduced the driftable fines in the spray pattern (Figure 3). Note that the nozzles were spaced 40 inches apart on the boom, which is greater than a typical spray system but still gave a 6-foot uniform application (Figure 2) at an 8-to-10-foot flying height. Note that if you attain a sprayer drone and want the application pattern and droplet size tested, LSU AgCenter has the facilities and equipment to determine these properties.

Figure 2: Droplet cards spaced every 1 ft. at a 8- to 10-foot flying height yielding a 6 ft. spray pattern (Vmd 0.5 = 467 um; Vmd 0.1 = 251 um; Vmd 0.9 = 644 um; 0.1 GPM per nozzle; 3.2 gpa).

Figure 3: Droplet cards from drift pole located 30 feet downwind compared to other nozzles tested — four consecutive passes; 4 to 6 mph crosswind; 58 percent RH; 82oF; 0.002 GPA drift per pass.

Building your own drone can be fun and informative, and a sprayer drone can add spraying utility to your farm that was not possible before. Note that regulations do exist for spraying commercially, and you will need Federal Aviation Administration Part 137 and Part 107 certifications along with other state and local certifications and an FAA flight test of the drone.